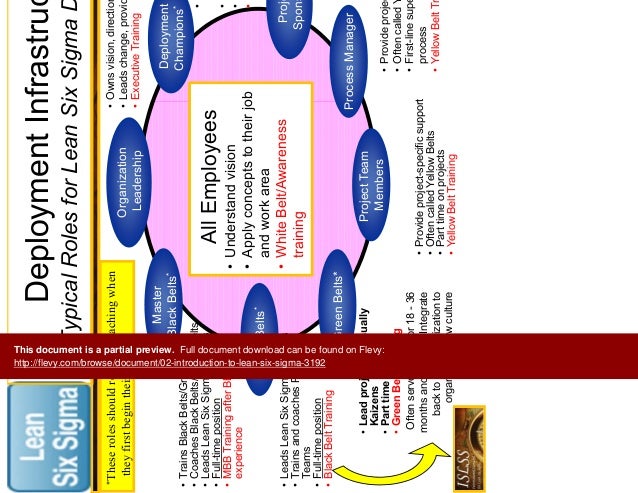

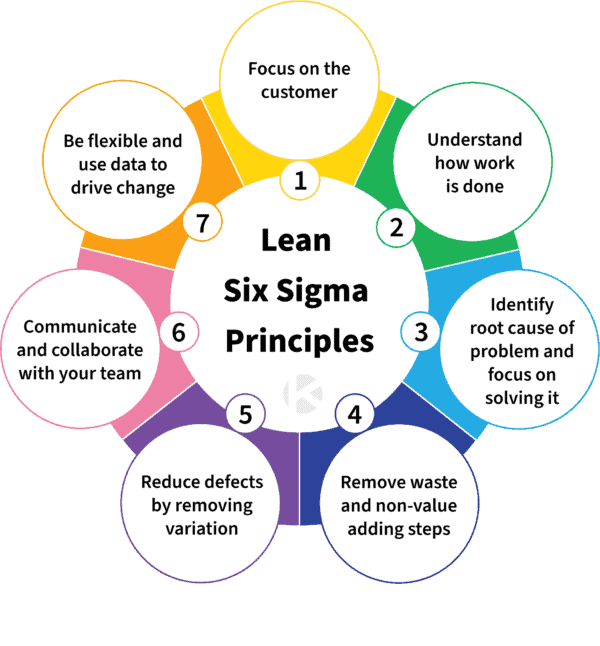

To promote flow, garbage must be removed. The five main principles or goals of Lean Six Sigma are as follows: Concentrate on the consumer. The lean six sigma green belt principles are considered one of the most effective ways to execute a project. There are no Eligibility Criteria for IASSC Certified Lean Six Sigma Green Belt (ICGB) Exam. Key Principles or Goals of Lean Six Sigma. The three different levels of certification for Lean Six Sigma would be : This is a Quality Strategy which is used to enhance the processes and implemented in Six Sigma and Lean Six Sigma to ensure the quality of the project. There are lots of different ways to improve your processes, and you’ve likely heard of Six Sigma methodology as one possibility, particularly for large manufacturing businesses, like GE and Motorola, looking to reduce defects and improve the quality of their products. Attaining the Lean Six Sigma Green Belt certification will help an individual to enhance the skills and thereby enables him to perform roles like a Quality Manager, Lean Manufacturing Specialist, Lean Manufacturing co-ordinator, Quality Analyst etc.ĭ-M-A-I-C is an acronym for Define, Measure, Analyze, Improve and Control.

#Lean 6 sigma principles professional#

A Lean Six Sigma Greenbelt certified professional will have a thorough understanding of all the different phases of D-M-A-I-C. It is perfectly suitable for individuals who want to make their career in Quality Management. It is a systematic approach that relies on a collective team effort to improve the performance by removing waste. 6 S lean not only helps organizations promote. While adhering to the 5S principle of Sort, Set in order, Shine, Standardize, and Sustain, the 6S method adds the concept of Safety. Lean Six Sigma combines the mindsets and methodologies of problem-solving from Lean and Six Sigma to create a complementary system that delivers a deeper look. The Lean Six Sigma is a methodology which includes information about the basic principles of both Six Sigma and Lean Six Sigma. 6S (otherwise known as 5S + Safety) is a system that aims to promote and sustain a high level of productivity and safety throughout a workspace.

0 kommentar(er)

0 kommentar(er)